CDI technology overview

What is capacitive deionization (CDI)?

CDI is used for the desalination of brackish water and industrial water treatment at a lower economic and environmental cost than any other available technologies

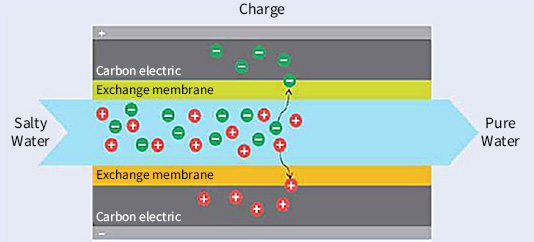

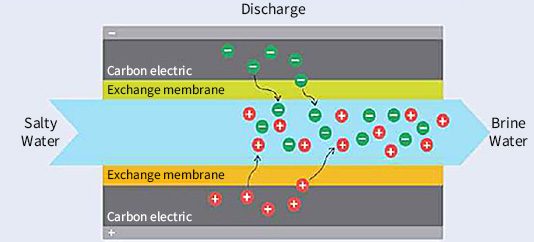

Based on the electric double layer formation principle, low voltage (1.5 V) is applied to porous carbon electrodes to desalinize by making ions in the solution attached to the electrode surface

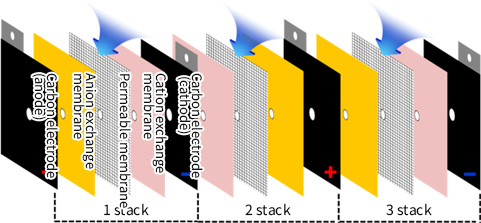

Operation Principle

Strengths of CDI technology

- Low energy consumption - Operation at low potential (1 ~ 2V) where electrode reaction does not occur

Low energy consumption of less than 0.1 kWh / m3 (6.6 to 9.3 kWh / m3 for RO and Distillation 7.9 to 10.8 kWh / m3) - Next Generation Technology to Replace RO

- Alternative energy available - Can be operated with solar or other alternative energy

- Environmentally friendly - Environmentally friendly without using chemicals

- Ease of process operation - Ion adsorption / desorption is possible by adjusting the electrode potential, so operation of the process is very simple

Product – Unit & Block Cell

ECOMITE-UI

ECOMITE-100BI

ECOMITE-LB

ECOMITE-300CI

| MODEL | TYPE | Feed Water | Flow Rate(L/min) | Size(mm) | TDS Removal |

|---|---|---|---|---|---|

| Ecomite-UI | Unit cell | TDS 2000ppm | 0.01 | W160*L160*H40 | >95% |

| Ecomite-100BI | Block cell | TDS 2000 ppm | 1.0(1.5ton/day) | W190*L160*H95 | >95% |

| Ecomite-LB | Block cell w/o IEM | Hardness 300ppm | 1.0 | W190*L172*H60 | >70% |

| Ecomite-300CI | Block cell | TDS 2000 ppm | 3.0 | D216Ø*H360 | >90% |

Applications

| Operation type | Batch type |

|---|---|

| Flow rate(ton/hr) | 1 |

| CDI module(ea) | 60 |

| Max. Removal efficiency(%) | >60(NH4-N) |